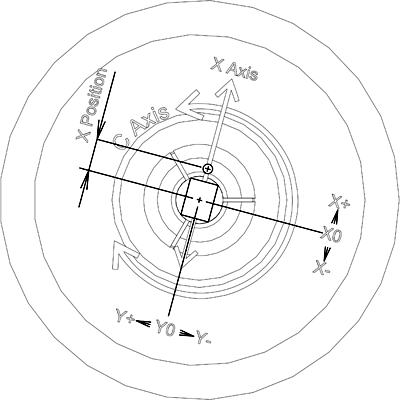

The XC mode is started with the command (~PLXC).

Before entering this command the live tool must be located on the negative X side of the part, with its spindle centerline parallel to the lathe’s Z axis.

On entry, the Y position is 0, and the X position is the distance from the spindle center to the center of the tool.

The Z axis remains the same as in normal turning mode. The computer constantly calculates the tool’s X-Y position along the programmed path, and the X-Y coordinates are converted to polar coordinates, with X axis motion controlling the distance from center and C axis rotation controlling the angle.

As seen from the tool’s point of view, motion to the right is X+ and up is Y+.

Back to plane-switch overview

Back to plane-switching commands

C-Axis XC Plane Switching Examples

The following programs use a 1/8" endmill to cut various shapes on the end of a 5/8" bar. Note that the programmed dimensions allow for the cutter size.

Note: if you copy these programs, do not include comments in the plane switched section. Nothing is allowed in the plane-switched program except the program statements described above.

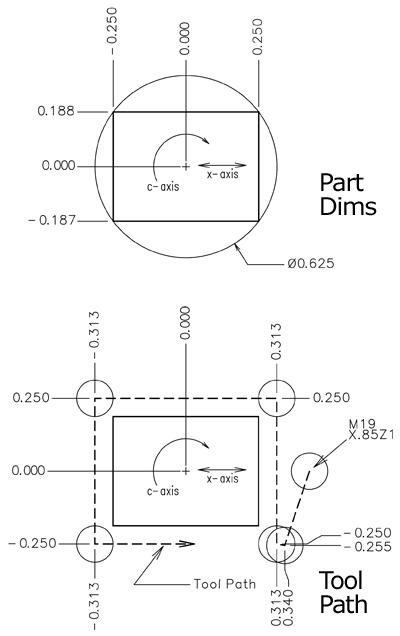

Program to cut a rectangle:

The first program cuts a 3/8 x 1/2" rectangle (5/8" diagonal measurement). Note that it begins cutting at a corner of the square and goes around the outside of the square in a CCW direction. Starting at the corner minimizes the initial chip load, which reaches its maximum at the center of each side. Going around the part CCW (conventional cutting) avoids the tendency of small cutters to dig in and snap off when climb cutting.

m19 (c-axis at 0° absolute)

t21 (live tool)

x-.85z1 (safe location)

f100z.05

f10z-.1 (at depth)

m27 (turn on live tool)

(~PLXC) start XC mode

(x.340y-.255) safe near corner

(x.313y-.250) at first corner

(x.313y.250) next corner

(x-.313y.250) third corner

(x-.313y-.250) fourth

(x.313y-.250) back at first

(end) end plane-switch mode

f200Z1.5

m30

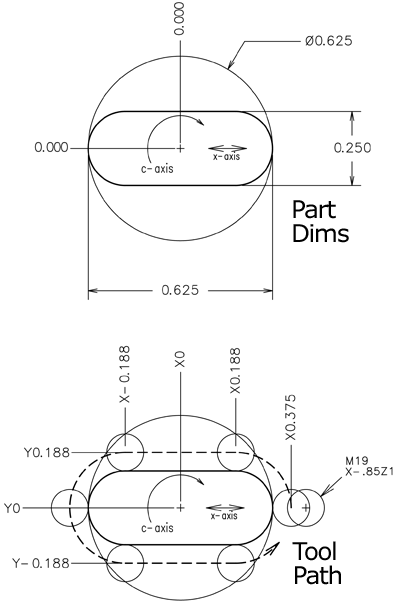

Program to cut an oval 5/8" long by 1/4" wide:

m19 (c-axis at 0° absolute)

t21

x-.85z1

f100z.05

f5z-.1

m27 (turn on live tool)

(~PLXC) start XC mode

(x.375y0) 0.3125" +cutter radius (0.0625)

(g03x.1875y.1875i.1875j0) ccw 90° @0.1875 radius

(x-.1875)

(g03x-.375y0i-.1875j0)

(g03x-.1875y-.1875i-.1875j0)

(x.1875)

(g03x.375y0i.1875j0)

(x.4)

(end) end plane-switch mode

f200Z1.5

m30

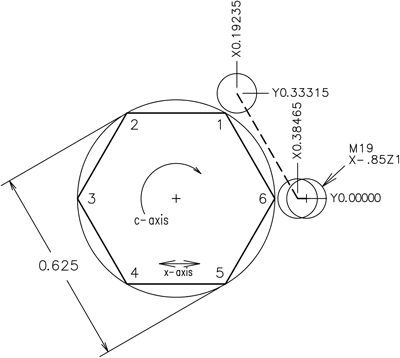

Program to cut six flats using looping:

As each flat is cut, the spindle turns 1/6 of a revolution; canceling plane-switch mode does not cause the spindle to move, so on the next iteration of the loop, the next flat is cut.

g90g94g72f300

m03s1000

g04f5

m05

m27

m19

t21

x-.85z1

f100z.05

f5z-.1

ls6

(~PLXC)

(x.38465y0)

(x.19235y.33315)

(end)

x-.8

lf

m05

f200Z1.5

m30